What we do- Manufacture components in UK and low cost India

LPC have been machining precision components since 1964 from our modern ISO 9001 (2015) accredited facility in Leicester, UK. We have a dedicated team of managers and engineers that produce machined components on multi-axis CNC machines ready for your assembly lines.

LPC introduced a low-cost facility in India in 2013 to cater for ongoing high-volume manufacture of aluminium components. The company’s investment in a low-cost manufacturing facility in India was a must to do requirement, safeguarding our supply of high-volume products to the automotive sector. The India facility houses our aluminium foundry utilising high pressure, low pressure and gravity diecasting production equipment. This is matched with our machining facility that houses modern CNC multi axis turning and machining equipment. The facility also has a paint finishing plant.

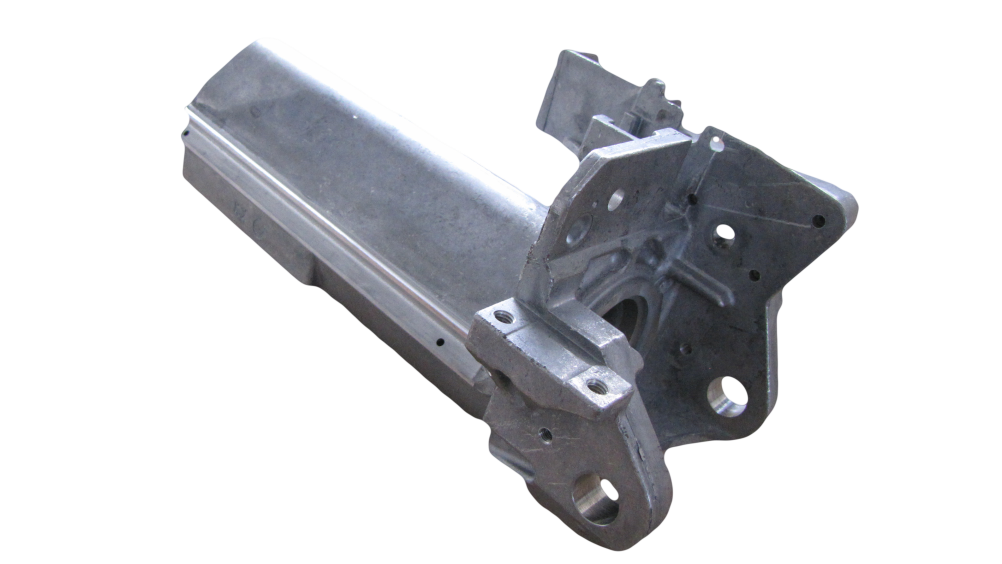

The India facility is accredited to IATF 16949 and ISO9001(2015). The facility is manned by a team of 500 dedicated, highly skilled managers and engineers. Our products are delivered directly to our European automotive customer assembly lines. We are experts in machining aluminium and cast-iron castings, such as brakes parts, engine boosting (turbo compressor covers), steering column components and are now manufacturing aluminium alloy wheels in India.

The UK plant has been diversified to tackle the challenges in the UK marketplace. The UK plant is now available to produce lower volume components for non-automotive clients as well as aftermarket requirements. The LPC facility is strategically placed to handle clients requiring higher volume products from our India facility.

LPC UK and India specialize in component manufacture from prototype, small batches, through to volume serial/volume production, we also support our customers with lower volumes required for aftermarket requirements.

Our philosophy includes our understanding and application of environmental standards as well our social responsibility to our community in which we operate. We actively take on apprentices, helping them on the step in their engineering careers.

Suppliers to the Automotive Community

Production Engineering Plant

LPC’s facilities use CNC technology, CAD/CAM and IATF16949/ISO9001 in our manufacturing processes. The current methods of production used by LPC include:

1. CNC Double Pallet, 3, 4 and 5 axes Vertical Machining Centres.

2. CNC 4 axes Horizontal Machining Centres.

3. CNC Multi-Axis and Robot Loaded Turning Centres.

4. Robust Fixturing Methodologies.

5. Highly trained and motivated work force.

The investment in multi-pallet and robot loaded cells, minimises operator involvement and ensures a lean manufacturing process, leading to more competitive pricing with respect to producing parts offshore.

TAKISAWA TWIN SPINDLE ROBOT LOADING TURNING CENTRES

PRODUCTION USING 4/5 AXIS TECHNOLOGY AND MULTI PALLETS (10 MACHINES IN PRODUCTION CELL)

OKK HIGH SPEED TWIN APLLET HORIZONTAL MACHINING CENTRES

MULTI-AXIS TURNING CENTRES

MEC WASH ULTRASONIC AND VACUUM PARTS WASHING

LPC’s compressor covers and turbine housing experience

AC/HVAC and Engine Cooling Components

Components for construction vehicles

Gallery of Components

LPC Plant

India Plant

120,000 square feet building house our foundry and machining units. Our India plant has been developed with green in mind