What we do

We are committed to providing quality components ready for assembly at low cost to our customers. We can take on projects from conception and develop these with our customers through to volume production and after sales service, providing lifetime product management.

LPC use flexible CNC production cells to manufacture components that are delivered direct to customer assembly lines. All aspects of the manufacturing process are supervised by our dedicated management and production teams.

Our manufacturing facility is backed by CAD/CAM, and we are also linked to our customers via EDI, used to identify scheduling information, orders and self-billed invoicing.

LPC has an excellent quality control facility, which uses the latest in CNC 3 axis co-ordinate measuring machines to back up our production requirements.

The Quality Assurance department employs advanced quality planning tools enabling defect prevention. LPC's continuous improvement policy ensures we are targeting zero defect components.

LPC has acquired a range of Blue-Chip customer approvals in recognition of our Quality excellence and are accredited to ISO9001in the UK. Our India plant accredited to IATF16949 and ISO14001.

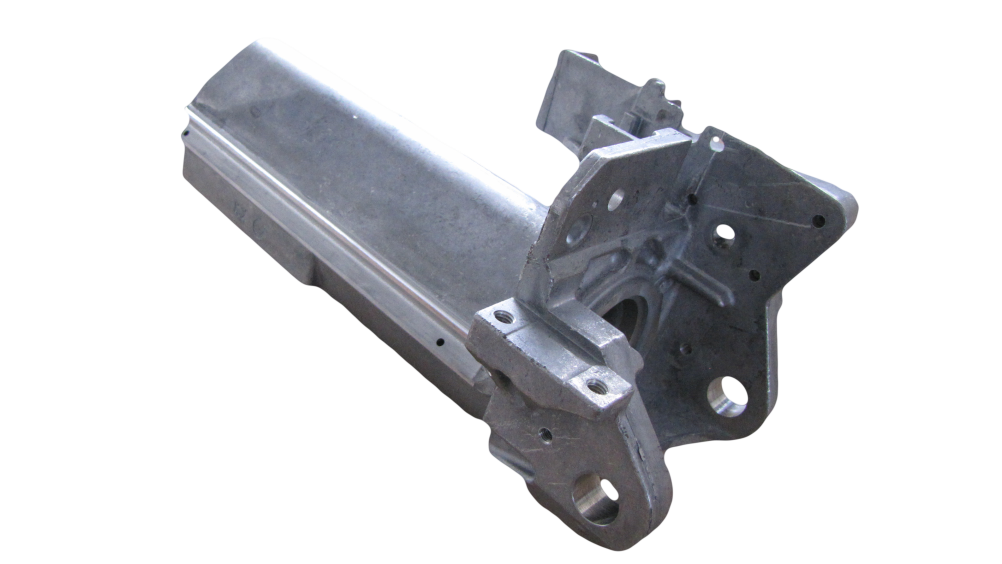

Our India plant has our own aluminium foundry producing castings using high and low pressure as well as in gravity die. India also fully machine and deliver parts to our European customers. Our India plant delivers components to global customers to include the UK.

Suppliers to the Automotive Community

Production Engineering Plant

LPC’s facilities use CNC technology, CAD/CAM and IATF16949/ISO9001 in our manufacturing processes. The current methods of production used by LPC include:

1. CNC Double Pallet, 3, 4 and 5 axes Vertical Machining Centres.

2. CNC 4 axes Horizontal Machining Centres.

3. CNC Multi-Axis and Robot Loaded Turning Centres.

4. Robust Fixturing Methodologies.

5. Highly trained and motivated work force.

The investment in multi-pallet and robot loaded cells, minimises operator involvement and ensures a lean manufacturing process, leading to more competitive pricing with respect to producing parts offshore.

LPC’s compressor covers and turbine housing experience

AC/HVAC and Engine Cooling Components

Gallery of Components

LPC Plant