Case Study – Compressor Cover

- LPC developed its own casting and machining process for compressor covers.

- LPC was able to demonstrate its engineering expertise by redesigning the customer specification to allow the casting process to be simplified.

- Magma Flow simulations were carried out to develop runner and feeder systems to optimise the die designs.

- LPC managed the project from inception through to current volume production at a weekly rate of 6000 parts per week.

- LPC received a prestigious customer accolade recognising its engineering and commercial success on this project, where customer expectations and milestones were exceeded.

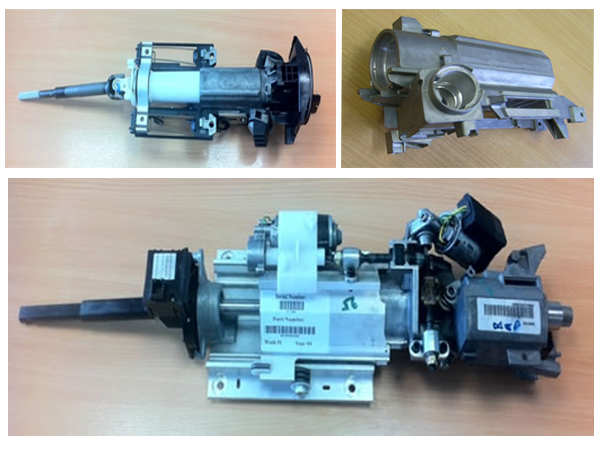

Case Study – Steering Column Projects

LPC produced and supplied various steering & column shaft components for two major european OEM's.

- Machinery used – Star S20 Sliding head machine.

- Machined 450,000 parts during 3 years of production.

- Demonstrated zero defect on the supply of this project

resulting in a score of zero PPM. - Used returnable packaging.